- Tel: 0086-13916147965

- Email: sales@venttk.com

- WhatsApp: 0086 13916147965

- Mob: 0086 13916147965

|

Air discharge direction |

|

|

Performance ranges |

Cooling capacity: from 42 to 607 kw Air volume: from 21454 to 227449 m3/h Sound pressure level: from 50 to 62 dB A(10m) Dry coolers:customized on demand |

|

High efficiency heat exchanger |

Capacity designs for maximizing the heat transfer relative to the energy consumption of the fan. Tube and tube coupling design for low pressure drop in the coil on the media sides(maximum 100KPa at water designing condition). Our thermodynamic and aerodynamic designing software is long year tested and proved in Germany |

|

Fan |

Only choose low specific energy consumption fans. Fan nozzle designs for maximum air flow and air throw. Our fans from the world`s leading manufacturer are practically proved to be reliable in operation and long lasting. Motor: protection class IP 54 and insulation class F. Voltage:400V/3N/50Hz Air separator for each fan. |

|

Testing |

Heat exchangers are supplied clean and tested at a pressure of 30 bars |

|

Options |

Coil design refrigerant: water, oil, glycol. Multiple circuits. Sub-cooling circuits. Stainless steel or aluminum casing. Coated aluminum or copper fins. Explosion ploof motor. Customized fin spacing. |

|

Air discharge direction |

|

|

Performance ranges |

Cooling capacity: from 42 to 607 kw Air volume: from 21454 to 227449 m3/h Sound pressure level: from 50 to 62 dB A(10m) Dry coolers:customized on demand |

|

High efficiency heat exchanger |

Capacity designs for maximizing the heat transfer relative to the energy consumption of the fan. Tube and tube coupling design for low pressure drop in the coil on the media sides(maximum 100KPa at water designing condition). Our thermodynamic and aerodynamic designing software is long year tested and proved in Germany |

|

Fan |

Only choose low specific energy consumption fans. Fan nozzle designs for maximum air flow and air throw. Our fans from the world`s leading manufacturer are practically proved to be reliable in operation and long lasting. Motor: protection class IP 54 and insulation class F. Voltage:400V/3N/50Hz Air separator for each fan. |

|

Testing |

Heat exchangers are supplied clean and tested at a pressure of 30 bars |

|

Options |

Coil design refrigerant: water, oil, glycol. Multiple circuits. Sub-cooling circuits. Stainless steel or aluminum casing. Coated aluminum or copper fins. Explosion ploof motor. Customized fin spacing. |

|

Type |

SHSL-D3-042-1X800 | SHSL-D3-046-1X800 | SHSL-D3-051-1X800 | SHSL-D3-087-2X800 | SHSL-D3-094-2X800 | SHSL-D3-103-2X800 | SHSL-D3-125-3X800 | SHSL-D3-146-3X800 | SHSL-D3-153-3X800 | SHSL-D3-175-4X800 | SHSL-D3-188-4X800 | |||||||

|

Capacity |

Water | 35℃ outdoor temp. | Inlet | 45℃, | KW | 42.1 | 46.1 | 50.6 | 87.3 | 93.6 | 102.9 | 124.9 | 145.9 | 153.3 | 174.5 | 187.9 | ||

| outlet | 40℃ | |||||||||||||||||

| 20% Glycol | Inlet | 45℃ | 40.8 | 45.1 | 49.7 | 84.5 | 91.8 | 100.9 | 119.4 | 143.0 | 150.4 | 168.9 | 184.3 | |||||

| outlet | 40℃ | |||||||||||||||||

|

Medium |

Water flow | M3/h | 7.3 | 8.0 | 8.8 | 15.2 | 16.3 | 17.9 | 21.7 | 25.4 | 26.6 | 30.3 | 32.7 | |||||

| Pressure drop | kPa | 49 | 69 | 97 | 48 | 98 | 93 | 21 | 97 | 89 | 48 | 98 | ||||||

| Air flow | M3/h | 21454 | 20531 | 19696 | 42906 | 41061 | 39390 | 64364 | 61585 | 59087 | 85811 | 82120 | ||||||

|

Fan motor(400V/3N/50HZ) |

W | 1800 | 1800 | 1800 | 3600 | 3600 | 3600 | 5400 | 5400 | 5400 | 7200 | 7200 | ||||||

| A | 3.8 | 3.8 | 3.8 | 7.6 | 7.6 | 7.6 | 11.4 | 11.4 | 11.4 | 15.2 | 15.2 | |||||||

| Fan | No X φ | 1x1x800 | 1x1x800 | 1x1x800 | 1x2x800 | 1x2x800 | 1x2x800 | 1x3x800 | 1x3x800 | 1x3x800 | 2x2x800 | 2x2x800 | ||||||

| Sound pressure level | dB(A) | 50.0 | 50.0 | 50.0 | 51.0 | 51.0 | 51.0 | 53.0 | 53.0 | 53.0 | 54.0 | 54.0 | ||||||

| 10m | ||||||||||||||||||

|

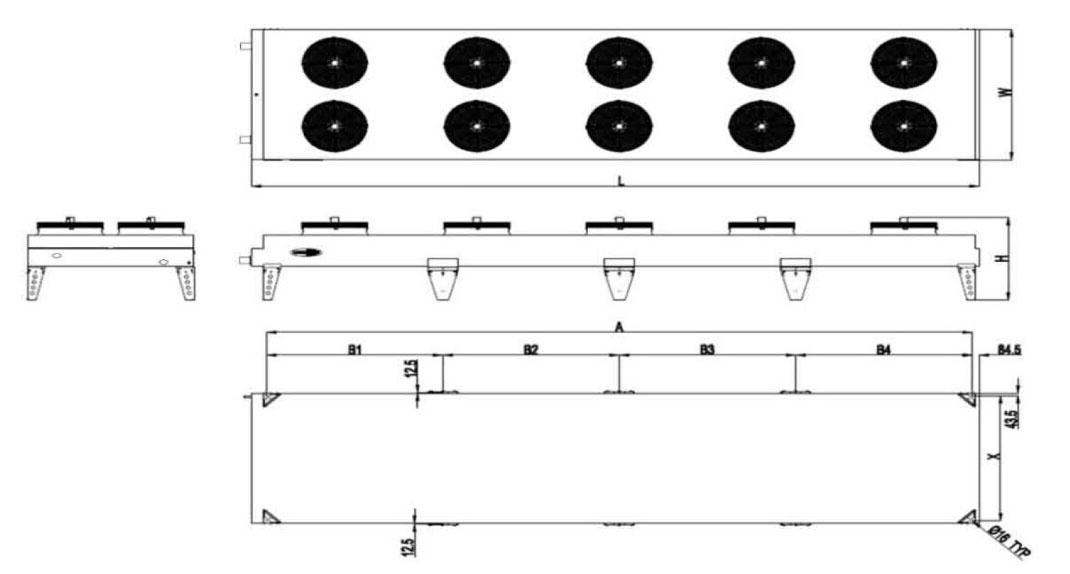

Dimension |

L | mm | 2000 | 2000 | 2000 | 3800 | 3800 | 3800 | 5600 | 5600 | 5600 | 3800 | 3800 | |||||

| W | mm | 1084 | 1084 | 1084 | 1084 | 1084 | 1084 | 1084 | 1084 | 2108 | 2108 | 2108 | ||||||

| H | mm | 1328 | 1328 | 1328 | 1328 | 1328 | 1328 | 1328 | 1328 | 1328 | 1328 | 1328 | ||||||

| A | mm | 1728 | 1728 | 1728 | 3528 | 3528 | 3528 | 5328 | 5328 | 5328 | 3528 | 3528 | ||||||

| B1 | mm | -- | -- | -- | 1764 | 1764 | 1764 | 1776 | 1776 | 1776 | 1764 | 1764 | ||||||

| B2 | mm | -- | -- | -- | 1764 | 1764 | 1764 | 1776 | 1776 | 1776 | 1764 | 1764 | ||||||

| B3 | mm | -- | -- | -- | -- | -- | -- | 1776 | 1776 | 1776 | -- | -- | ||||||

| B4 | mm | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | -- | ||||||

| X | mm | 997 | 997 | 997 | 997 | 997 | 997 | 997 | 997 | 997 | 2021 | 2021 | ||||||

| Inlet φ | mm | 2” | 2” | 2” | 2 1/2” | 2 1/2” | 2 1/2” | 3’ | 3’ | 3’ | 4” | 4” | ||||||

| Inlet φ | mm | 2” | 2” | 2” | 2 1/2” | 2 1/2” | 2 1/2” | 3’ | 3’ | 3’ | 4” | 4” | ||||||

| Product weight(empty) | kg | 225 | 233 | 241 | 357 | 373 | 392 | 796 | 527 | 749 | 812 | 1062 | ||||||

|

Type |

SHSL-D3-206-4X800 | SHSL-D3-250-6X800 | SHSL-D3-292-6X800 | SHSL-D3-307-6X800 | SHSL-D3-340-8X800 | SHSL-D3-389-8X800 | SHSL-D3-406-8X800 | SHSL-D3-431-8X800 | SHSL-D3-491-10X800 | SHSL-D3-512-10X800 | SHSL-D3-607-12X800 | ||||||||||

| Capacity | Water | 35℃ outdoor temp. | Inlet | 45℃, | KW | 205.8 |

249.8 |

291.9 | 306.6 | 340.5 | 389.1 | 406.0 | 431.3 | 490.6 | 511.6 | 606.9 | |||||

| outlet | 40℃ | ||||||||||||||||||||

| 20% Glycol | Inlet | 45℃ | 201.9 | 238.8 | 286.1 | 300.8 | 329.7 | 381.5 | 398.5 | 420.5 | 482.9 | 504.1 | 597.5 | ||||||||

| outlet | 40℃ | ||||||||||||||||||||

| Medium | Water flow | M3/h | 35.8 | 43.4 | 50.7 | 53.3 | 59.2 | 67.6 | 70.6 | 75.0 | 85.3 | 88.9 | 105.5 | ||||||||

| Pressure drop | kPa | 92 | 21 | 98 | 88 | 46 | 99 | 79 | 82 | 99 | 98 | 97 | |||||||||

| Air flow | M3/h | 78781 | 128728 | 123170 | 118174 | 171631 | 160328 | 153274 | 214533 | 200405 | 191587 | 227449 | |||||||||

| Fan motor(400V/3N/50HZ) | W | 7200 | 10800 | 10800 | 10800 | 14400 | 14400 | 14400 | 18000 | 18000 | 18000 | 21600 | |||||||||

| A | 15.2 | 22.8 | 22.8 | 22.8 | 22.80 | 30.40 | 30.40 | 38.00 | 38.00 | 38.00 | 45.60 | ||||||||||

| Fan | No X φ | 2x2x800 | 2x3x800 | 2x3x800 | 2x3x800 | 2x4x800 | 2x4x800 | 2x4x800 | 2x5x800 | 2x5x800 | 2x5x800 | 2x6x800 | |||||||||

| Sound pressure level | dB(A) | 54.0 | 56.0 | 56.0 | 56.0 | 58.0 | 58.0 | 58.0 | 60.0 | 60.0 | 60.0 | 62.0 | |||||||||

| 10m | |||||||||||||||||||||

| Dimension | L | mm | 3800 | 5600 | 5600 | 5600 | 7400 | 7400 | 7400 | 9200 | 9200 | 9200 | 11000 | ||||||||

| W | mm | 2108 | 2108 | 2108 | 2108 | 2108 | 2108 | 2108 | 2108 | 2108 | 2108 | 2108 | |||||||||

| H | mm | 1328 | 1328 | 1328 | 1328 | 1328 | 1328 | 1328 | 1328 | 1328 | 1328 | 1328 | |||||||||

| A | mm | 3528 | 5328 | 5328 | 5328 | 7128 | 7128 | 7128 | 8929 | 8929 | 8929 | 10728 | |||||||||

| B1 | mm | 1764 | 1776 | 1776 | 1776 | 2376 | 2376 | 2376 | 2232 | 2232 | 2232 | 2682 | |||||||||

| B2 | mm | 1764 | 1776 | 1776 | 1776 | 2376 | 2376 | 2376 | 2232 | 2232 | 2232 | 2682 | |||||||||

| B3 | mm | -- | 1776 | 1776 | 1776 | 2376 | 2376 | 2376 | 2232 | 2232 | 2232 | 2682 | |||||||||

| B4 | mm | -- | -- | -- | -- | -- | -- | -- | 2232 | 2232 | 2232 | 2682 | |||||||||

| X | mm | 2021 | 2021 | 2021 | 2021 | 2021 | 2021 | 2021 | 2021 | 2021 | 2021 | 2021 | |||||||||

| Inlet φ | mm | 4” | DN125 | DN125 | DN125 | DN125 | 2x4” | 2x4” | 2x4” | 2xDN125 | 2xDN125 | 2xDN125 | |||||||||

| Inlet φ | mm | 4” | DN125 | DN125 | DN125 | DN125 | 2x4” | 2x4” | 2x4” | 2xDN125 | 2xDN125 | 2xDN125 | |||||||||

| Product weight(empty) | kg | 1127 | 1373 | 1462 | 1704 | 1785 | 1816 | 2150 | 2230 | 2380 | 2590 | 2780 | |||||||||